Embarking on a quest to find the perfect plaster for your ceiling, especially in those notoriously damp areas of your home, can feel like navigating through a dense, misty jungle of options. Moisture, the uninvited guest that it is, can wreak havoc on the wrong plaster type, leading to many issues that no homeowner ever wants to face.

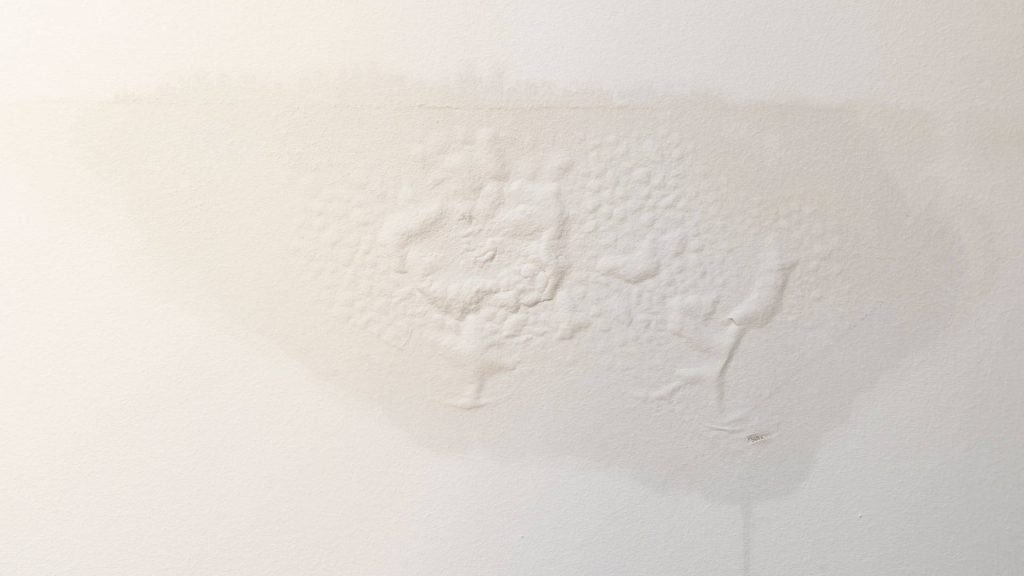

From the creeping menace of mould and mildew to the unsightly peeling and bubbling of paint, the stakes are high when choosing the right armour for your ceiling against the persistent onslaught of humidity and water exposure.

In this blog, we’re about to cut through the fog of uncertainty, shining a light on the path to making an informed decision that marries durability with aesthetics. This isn’t just about finding a plaster that can withstand wet conditions; it’s about uncovering the champion that will protect and enhance your space for years.

Join us as we dive deep into the world of plasters, comparing their strengths, weaknesses, and the unique qualities that make one the unmistakable victor in the battle against moisture.

Understanding Wet Areas In Homes And Buildings

Wet areas in homes and buildings are spaces exposed to moisture, water, or rain, directly or indirectly. These areas include bathrooms, kitchens, laundries, water closets, and balconies. Proper management of these spaces is crucial to prevent structural damage, maintain aesthetic appeal, and ensure the health and safety of occupants.

What Constitutes A Wet Area?

Wet areas are defined by their exposure to water and moisture. This exposure can come from direct wetting (such as showering), high humidity levels, or condensation. The common wet areas in a building include:

- Bathrooms: These are primary wet areas due to direct water exposure from showers, baths, and sinks.

- Kitchens: Exposure to water and moisture occurs frequently around sinks, dishwashers, and cooking areas.

- Laundries: Like bathrooms, laundries face direct wetting from washing machines and sinks.

- Toilets: Although not exposed to as much water as bathrooms, toilets are still considered wet areas due to plumbing fixtures.

- Balconies: Outdoor spaces like balconies are exposed to rain and must be treated as wet areas.

Importance Of Proper Management

Improper design, construction, or maintenance of wet areas can lead to several problems, including:

- Structural Damage: Continuous exposure to water can weaken building materials, leading to rot in framing and deterioration of linings, flooring, and cabinetry.

- Health Issues: Damp environments are breeding grounds for mould and mildew, which can cause respiratory problems and other health issues.

- Aesthetic Damage: Water leakage and dampness can cause paint to flake and tiles to loosen, ruining the visual appeal of the space.

Criteria For Choosing Ceiling Plaster For Wet Areas

When renovating or constructing wet areas in homes and buildings, selecting the right ceiling plaster is crucial for ensuring durability, moisture resistance, and overall aesthetic appeal. Wet areas, characterised by their exposure to moisture and water, include bathrooms, kitchens, laundries, and similar spaces. Plaster choices in these areas must meet specific criteria to withstand their unique challenges.

Moisture Resistance

Its moisture resistance is the primary consideration for choosing ceiling plaster for wet areas. Water-resistant plasterboard is specifically designed for wet areas, incorporating special ingredients into the board’s core to limit water absorption and prevent damage. These plasterboards undergo rigorous testing, including submersion and surface exposure to water, to ensure they meet the required performance standards in high humidity and wet conditions.

Compliance With Building Codes

The chosen plasterboard must comply with the Building Code of Australia (BCA) or relevant national construction codes. These codes outline the requirements for plastering in wet areas, specifying the areas where waterproofing is necessary and the types of water-resistant materials to be installed. Ensuring compliance not only guarantees the structural integrity of the building but also safeguards against potential legal issues.

Special Additives For Enhanced Performance

To further enhance moisture resistance, some plasterboards are treated with special additives. These additives permeate the core and surfaces of the board, providing additional protection against moisture without compromising the plaster’s integrity. For areas with specific needs, such as schools, hospitals, and aged care facilities, antifungal moisture-resistant plasterboards are available to prevent mould growth, ensuring a healthier environment for occupants.

Suitability As A Substrate For Tiling

In many wet areas, plasterboards serve as a substrate for tiling. Water-resistant plasterboards with very low water absorption features are ideal for this purpose, as they do not undergo moisture movement. This stability is crucial for maintaining the durability and appearance of the tiled surface over time.

Fire And Acoustic Performance

Besides moisture resistance, some wet areas may require plasterboards that offer additional fire and acoustic performance. Some products are designed to meet these needs, providing a comprehensive solution that addresses multiple aspects of wet area construction.

Ease Of Installation And Compatibility

The chosen plaster should be compatible with the overall design of the wet area, ensuring easy installation and seamless integration with other materials. For example, some products are available in thicknesses that match standard plasterboard walls in non-wet areas, facilitating easier joining and finishing. Additionally, its sound resistance qualities can help reduce noise from bathrooms and toilets, contributing to a more comfortable living environment.

Environmental Considerations

For environmentally-conscious projects, water-resistant plasterboards contain a high percentage of recycled materials, offering a sustainable option without sacrificing performance. These boards also provide mould and high-impact resistance, making them a versatile choice for various applications.

Recommended Plaster Types For Wet Areas

When it comes to finishing wet areas in homes and buildings, such as bathrooms, kitchens, and laundries, choosing the right type of plaster is crucial for ensuring durability, moisture resistance, and overall aesthetic appeal. Wet areas require materials that can withstand high humidity, direct water exposure, and the risk of mould and mildew growth. Here, we explore recommended plaster types specifically designed for these challenging environments, combining insights from various sources to provide a comprehensive guide.

Cement-Based Plasters

Cement-based plasters are highly recommended for wet areas due to their excellent water resistance and durability. These plasters are suitable for surfaces that directly interact with water, such as shower walls. When compacted properly, cement-lime mixtures offer waterproof qualities essential for wet area applications. However, it’s important to note that pure cement plaster without proper compaction may not provide sufficient water resistance.

Moisture-Resistant Gypsum Plaster

While traditional gypsum plaster is less suitable for areas expected to be wet, moisture-resistant gypsum plaster variants are available. These are specially formulated to withstand occasional dampness, making them suitable for ceilings and walls in wet areas, provided they are not in direct contact with water. These plasters can be finished with waterproof coatings or sealants for enhanced protection.

Polymer-Enhanced Plasters

Polymer-enhanced plasters offer superior water resistance and are characterised by their flexibility, strength, and long-lasting performance. These plasters are made with acrylic, epoxy resins, or polyurethane, providing a highly effective barrier against moisture. Although not typically used for significant surface levelling, polymer plasters are excellent for decorative finishes and protective cladding in wet areas.

Wet Area Base Coat

The Wet Area Base Coat is a pre-mixed, moisture-resistant jointing compound designed for the first and second coats in a three-coat plasterboard jointing system. Its formulation provides excellent tape adhesion and joint strength, making it ideal for wet areas like bathrooms and laundries. This base coat can be applied by hand or machine and finished with any topping or all-purpose compound.

Eco-Friendly And Health-Conscious Options

There are eco-friendly and health-conscious plaster options for those concerned about environmental impact and indoor air quality. These include plasters with antifungal properties to prevent mould growth and those made from natural, sustainable materials. When selecting plaster for wet areas, consider products that contribute to a healthy living environment and are free from harmful chemicals.

Decorative Plasters

Decorative plasters offer both aesthetic appeal and functionality for wet areas. Options like lime plaster provide a beautiful finish and have natural antibacterial properties, making them suitable for damp environments. When choosing decorative plasters, ensure they are compatible with wet conditions or can be protected with appropriate sealants.

Application Tips For Wet Area Ceiling Plasters

Applying plaster to ceilings in wet areas requires meticulous preparation, the right tools, and a keen understanding of the plaster’s properties. Here are consolidated tips from various experts to help you achieve a flawless finish on your next project.

Preparation Is Crucial

Before starting, ensure the ceiling surface is clean and free from imperfections. Sand down any glossy painted areas to help the new plaster adhere better. A thorough wipe-down with a damp cloth to remove dust and cobwebs is essential for a clean working surface.

Use The Right Tools

A stainless steel plastering trowel, bucket trowel, hawk board, mixing device (like a forced action mixer or paddle mixer), and a water brush are essential. For mixing plaster, the Forced Action Mixer is recommended for its efficiency and portability, saving labour, time and energy.

Clean Equipment And Water

Always start with clean buckets, tools, and equipment to prevent the plaster from going off prematurely and to ensure a smooth finish. Use clean water to avoid contamination affecting the plaster’s setting time and consistency.

Mixing Plaster

Add plaster to water, not the other way around, to achieve a lump-free mix. Aim for a consistency similar to melted ice cream. If the mix can support a stick standing upright, it’s mixed perfectly.

Application Technique

Start plastering in a corner and work your way out in manageable sections. Apply the plaster using a putty knife, transfer it to the hawk, and then to the trowel before applying it to the ceiling. Maintain a consistent thickness of about ¼ inch across the ceiling for uniform drying and finishing.

Timing And Temperature

Apply plaster when it feels tacky but not too wet, which helps bond the surface to the wall. Keep the room cool to prevent the plaster from drying too quickly, which can lead to cracking.

Achieving A Good Finish

Use confident, firm pressure and the correct angle of the trowel. Don’t strive for perfection in the first coat; imperfections can be smoothed later. When troweling up the second coat, ensure the plaster is tacky and pliable enough to fill in holes without creating new ones.

Final Touches

After the first two coats:

- Begin the “troweling up” process to fill in holes and remove trowel marks.

- Watch for the plaster to darken in colour, indicating it’s ready for the final trowel.

- Avoid over-polishing to ensure paint and wallpaper adhere properly.

Supporting Equipment

Use stilts, scaffolding, or a stepladder to reach all ceiling areas comfortably. Ensure your trowel is clean, rust-free, and the correct type for the job. For beginners, an 11″ finishing trowel is recommended for easier control.

Practice And Patience

Like any skill, proficiency in plastering ceilings, especially in wet areas, requires practice and patience. Take your time with the process; take your time to ensure each step is done correctly for the best finish.

Conclusion

This guide is all about picking the right ceiling plaster for wet places in buildings and homes. It stresses how important it is to do things the right way to keep structures from getting damaged, keep the building looking nice, and keep people safe and healthy. Wet areas are places that get wet from water, wetness, or rain, like bathrooms, kitchens, laundry rooms, water closets, and porches. To avoid damage to buildings, health problems, and bad looks, it’s important to have good management.

When picking ceiling plaster for wet areas, things like how well it resists wetness, how well it meets building codes, whether it can be used as a base for tiles, how well it handles fire and sound, how easy it is to install and how compatible it is with other materials, and environmental concerns should all be taken into account. Water-resistant plasterboards are made to work in wet areas. They have special ingredients in the core of the board that stop water from soaking in and causing damage.

It’s also important to follow the Building Codes, which spell out the rules for painting in wet areas, including where protection is needed and what kinds of materials should be used. Special chemicals can make the plaster even more resistant to water without weakening it.

Plasterboards that are resistant to fire and sound may be needed in some wet places in addition to those that are resistant to water.

Finally, picking the right ceiling plaster for wet places is very important for making sure it lasts, doesn’t get damaged by water, and looks good overall.

The type of plaster used in wet parts of buildings and homes is very important for how long it lasts, how well it resists water damage, and how nice it looks. Cement-based plasters are highly suggested because they last a long time and don’t get damaged by water. Different types of moisture-resistant gypsum plaster can be used on ceilings and walls in damp places as long as they don’t come into direct touch with water. Plasters that have been strengthened with polymers are more resistant to water and are known for being strong, flexible, and long-lasting.

Plasters that kill fungi and those made from natural, long-lasting materials are both healthy and good for the environment. Lime plaster is one type of decorative plaster that can be used in wet places and looks good too. When picking out artistic plasters, make sure they can be used in wet areas or can be covered with the right sealants.

To put plaster on ceilings in wet areas, you need to carefully prepare the surface, use the right tools, and know a lot about how the plaster works. To get ready, you need to make sure the ceiling surface is smooth and clean, use the right tools, start with clean buckets, tools, and equipment, mix the plaster, apply it in manageable chunks, pay attention to timing and temperature, get a good finish, practice, and be patient. If you follow these tips, your next job will be finished perfectly.

Content Summary

- Embarking on a quest to find the perfect plaster for damp ceiling areas can feel like navigating a dense jungle.

- Moisture can wreak havoc on the wrong type of plaster, causing mould, mildew, and paint bubbling.

- This guide aims to shine a light on making an informed decision for ceiling plaster in wet areas.

- The goal is to find a plaster that marries durability with aesthetics, enhancing space for years.

- Wet areas in homes include bathrooms, kitchens, laundries, water closets, and balconies.

- Proper management of wet areas is crucial to prevent structural damage and maintain aesthetic appeal.

- Wet areas are defined by their exposure to water, moisture, or rain.

- Bathrooms, kitchens, and laundries are primary wet areas due to direct water exposure.

- Improper management of wet areas can lead to structural damage, health issues, and aesthetic damage.

- Moisture resistance is the primary criterion for choosing ceiling plaster for wet areas.

- Water-resistant plasterboard is designed for wet areas, limiting water absorption.

- Compliance with building codes is essential for the chosen plasterboard in wet areas.

- Special additives can enhance moisture resistance in plasterboards.

- Plasterboards must be suitable as a substrate for tiling in wet areas.

- Some wet areas require plasterboards with additional fire and acoustic performance.

- The chosen plaster should be easy to install and compatible with the overall design of the wet area.

- Environmentally-conscious projects can benefit from water-resistant plasterboards containing recycled materials.

- Cement-based plasters are recommended for their excellent water resistance in wet areas.

- Moisture-resistant gypsum plaster variants are suitable for ceilings in wet areas.

- Polymer-enhanced plasters offer superior water resistance and long-lasting performance.

- The Wet Area Base Coat is designed for moisture resistance in jointing systems.

- Eco-friendly and health-conscious plaster options are available for wet areas.

- Decorative plasters can provide aesthetic appeal and functionality in damp environments.

- Preparation is crucial when applying plaster to ceilings in wet areas.

- Use the right tools, such as a stainless steel plastering trowel and a hawk board.

- Ensure all equipment and water used in mixing and applying plaster are clean.

- Add plaster to water for a lump-free mix, aiming for a consistency similar to melted ice cream.

- Apply plaster starting in a corner, maintaining a consistent thickness across the ceiling.

- Keep the room cool to prevent plaster from drying too quickly and cracking.

- Use confident, firm pressure and the correct angle of the trowel for a good finish.

- The “troweling up” process is essential for achieving a smooth finish.

- Supporting equipment like stilts or scaffolding can aid in reaching all ceiling areas.

- Practice and patience are key to becoming proficient in plastering ceilings in wet areas.

- Selecting the right plaster for wet areas requires understanding their unique challenges.

- Compliance with the Building Code of Australia is crucial for wet area plastering.

- Antifungal moisture-resistant plasterboards are ideal for health-sensitive environments.

- Water-resistant plasterboards prevent damage from high humidity and wet conditions.

- Proper compaction is necessary when using cement-based plasters in wet areas.

- Polymer-enhanced plasters are not typically used for levelling but for decorative finishes.

- Eco-friendly plasters can also offer mould and high-impact resistance.

- Lime plaster is suitable for wet areas due to its natural antibacterial properties.

- Ensuring plaster is compatible with wet conditions is crucial for decorative options.

- A thorough wipe-down of the ceiling surface is essential before applying plaster.

- A Forced Action Mixer is recommended for efficient plaster mixing.

- Timing the application when plaster feels tacky but not wet is crucial for bonding.

- Avoid striving for perfection in the first coat; imperfections can be smoothed later.

- Watching for plaster to darken in colour indicates readiness for the final trowel.

- Avoid over-polishing to ensure proper adhesion of paint and wallpaper.

- An 11″ finishing trowel is recommended for beginners for easier control.

- The guide offers a comprehensive comparison of plasters to protect against moisture.

Frequently Asked Questions

What Are Wet Areas And Why Do They Require Special Ceiling Plaster?

Wet areas in a home or building are spaces exposed to moisture and water, such as bathrooms, kitchens, and laundries. These areas require special ceiling plaster because regular plaster may not withstand the high humidity and direct water exposure, leading to damage like mould growth, peeling, and structural deterioration.

What Makes A Ceiling Plaster Suitable For Wet Areas?

A suitable ceiling plaster for wet areas must have high moisture resistance to prevent water absorption. It should comply with building codes, possibly include special additives for enhanced moisture resistance, and be an appropriate substrate for tiling if needed. Additionally, it may offer fire and acoustic performance and be environmentally friendly.

Can I Use Regular Gypsum Plaster In My Bathroom Ceiling?

Regular gypsum plaster is not ideal for wet areas due to its lower moisture resistance. However, moisture-resistant gypsum plaster variants are specifically formulated to withstand occasional dampness. These should be finished with waterproof coatings or sealants for enhanced protection against moisture.

Are There Eco-Friendly Plaster Options For Wet Areas?

Yes, there are eco-friendly plaster options for wet areas that contain recycled materials and offer sustainable benefits without compromising on performance. These plasters also provide mould and high-impact resistance, making them a versatile choice for various applications.

How Should I Prepare My Ceiling Before Applying Plaster In A Wet Area?

Preparation is key to ensuring a successful plaster application. Clean the ceiling surface to remove dust and imperfections, and sand down any glossy painted areas to improve adhesion. Ensure that all equipment and water used for mixing and applying the plaster are clean to avoid contamination that could affect the plaster’s performance.